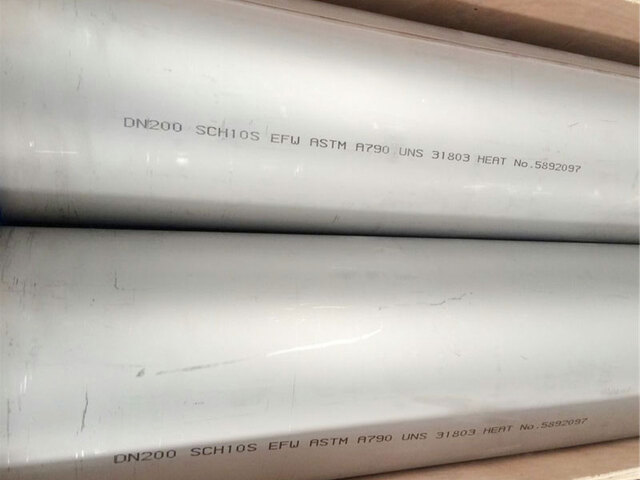

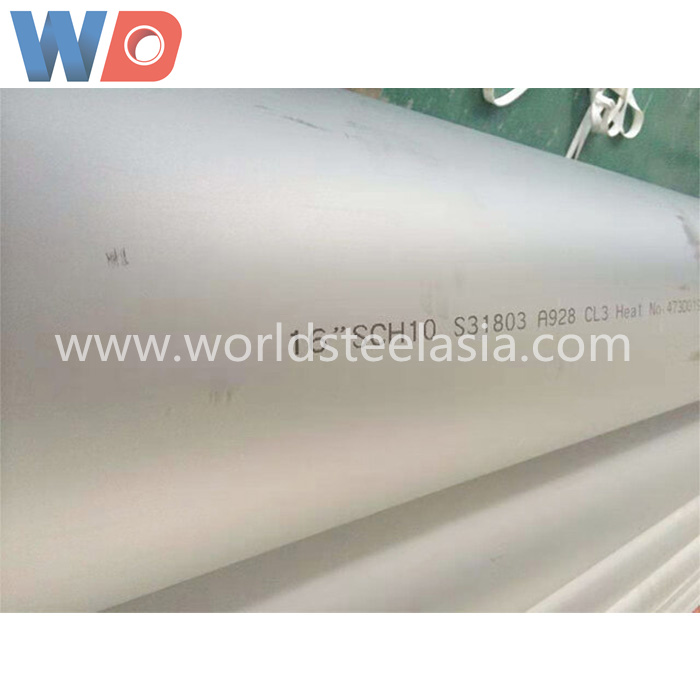

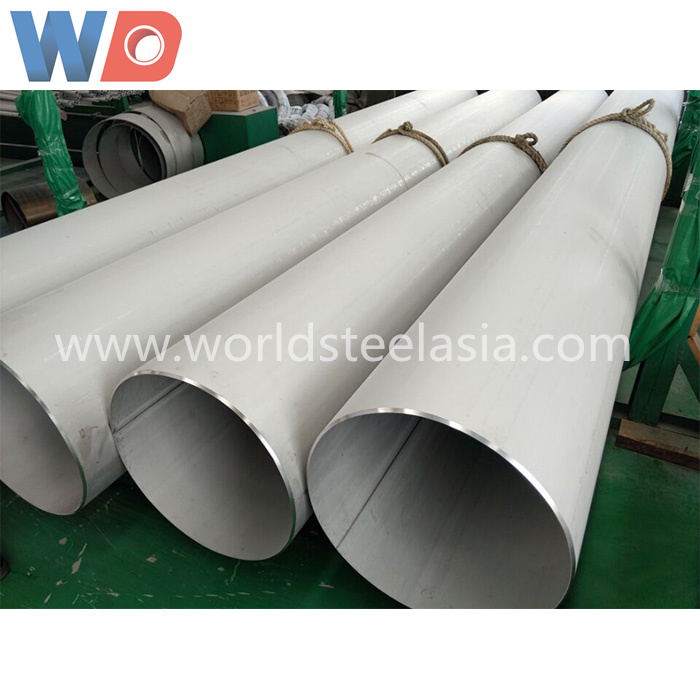

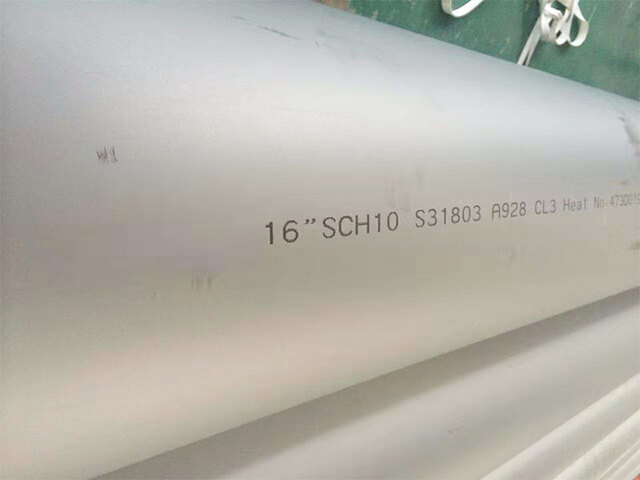

Welded Duplex Steel Pipe S31803 and S32750

ASTM A928 / A928M

Standard Specification for Ferritic/Austenitic (Duplex) Stainless Steel Pipe Electric Fusion Welded with Addition of Filler Metal

Duplex stainless steel has been widely used, of which 2205 duplex stainless steel is also the most widely used. Corrosion resistance of dual phase steel 1. Pitting corrosion resistance the pitting corrosion resistance of steel depends on the elements of chromium, molybdenum and nitrogen in the steel. The pitting index of several dual phase stainless steels and austenitic stainless steels is compared. PrEN value is generally used to predict the performance of steel in chloride environment. The pitting corrosion resistance of 2205 steel in chlorine environment is better than 18-5Mo section steel and 316L stainless steel. The relationship between CPT value and chloride ion content at 300mV potential shows that 2205 duplex stainless steel is better than 2304 duplex stainless steel.

Performance characteristics:

1. Excellent overall corrosion resistance and local corrosion resistance, especially stress corrosion resistance, pitting corrosion resistance, crevice corrosion resistance, corrosion fatigue resistance and wear resistance

2. Good weldability

3. Good comprehensive mechanical properties

4. Good intergranular corrosion resistance

5. High cost performance and long service cycle

Austenitic Stainless Steel - Corrosive Service Applications - Duplex And Super Duplex Stainless Steel - Electrofusion - Electrofusion Welding - Ferritic Stainless Steel - Stainless Steel Pipes - Steel Pipes - Tubular Products - Welded Pipes And Tubes - Welded Steel Pipes

1.2 This specification covers grades of ferritic/austenitic steel as indicated in Table 1. The selection of the proper alloy and requirements for heat treatment shall be at the discretion of the purchaser, dependent on the service conditions to be encountered.

1.3 Five classes of pipe are covered as follows:

1.3.1 Class 1—Pipe shall be double welded by processes using filler metal in all passes and shall be radiographed completely.

1.3.2 Class 2—Pipe shall be double welded by processes using filler metal in all passes. No radiograph is required.

1.3.3 Class 3—Pipe shall be single welded by processes using filler metal in all passes and shall be radiographed completely.

1.3.4 Class 4—Same as Class 3, except that the weld pass exposed to the inside pipe surface is permitted to be made without the addition of filler metal (see 6.2.2.1 and 6.2.2.2).

1.3.5 Class 5—Pipe shall be double welded by processes using filler metal in all passes and shall be spot radiographed.

| CHONGQING WORLD STEEL CO.,LTD | |||||||||||

| Chemical Requirements | |||||||||||

| Grade | UNS | Composition, %B | |||||||||

| C | Mn | P | S | Si | Cr | Ni | Mo | N | Copper | ||

| S31803 | S31803 | 0.03 | 2 | 0.03 | 0.02 | 1.00 | 21.0 – 23.0 | 4.5.0 – 6.5 | 2.5 – 3.5 | 0.08 – 0.20 | . . . |

| 2205 | S32205 | 0.03 | 2 | 0.03 | 0.02 | 1.00 | 22.0 – 24.0 | 4.5.0 – 6.5 | 3.0 – 3.5 | 0.14 – 0.20 | . . . |

| 2507 | S32750 | 0.03 | 1.2 | 0.035 | 0.02 | 0.80 | 24 – 28.0 | 6.0 – 8.0 | 3.0 – 5.0 | 0.24 – 0.32 | 0.5 |